Tokai’s Quality ControlTokai’s Quality Control

Thorough our quality control is what we put a lot of effort into in order to stably supply products that meet the needs of our customers and earn their trust.

In order to ensure the quality and functions after film formation, we have accumulated know-how from inspection to various measurements, and we conduct quality control according to the standards set based on ISO9001.

We have received orders from customers in a wide range of genres and have delivered high value-added and competitive products in any era.

And we have been highly praised by many industries for our quality standards and our multiple and various processed products, as well as many delivery results stand as actual proofs.

Tokai’s strength is its ability to provide “high quality” products.

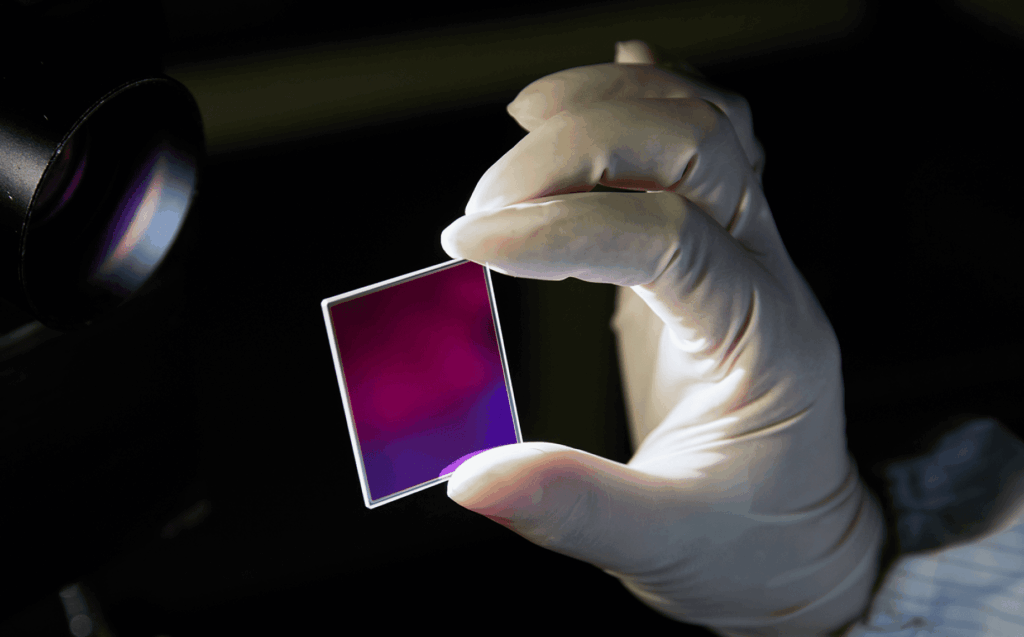

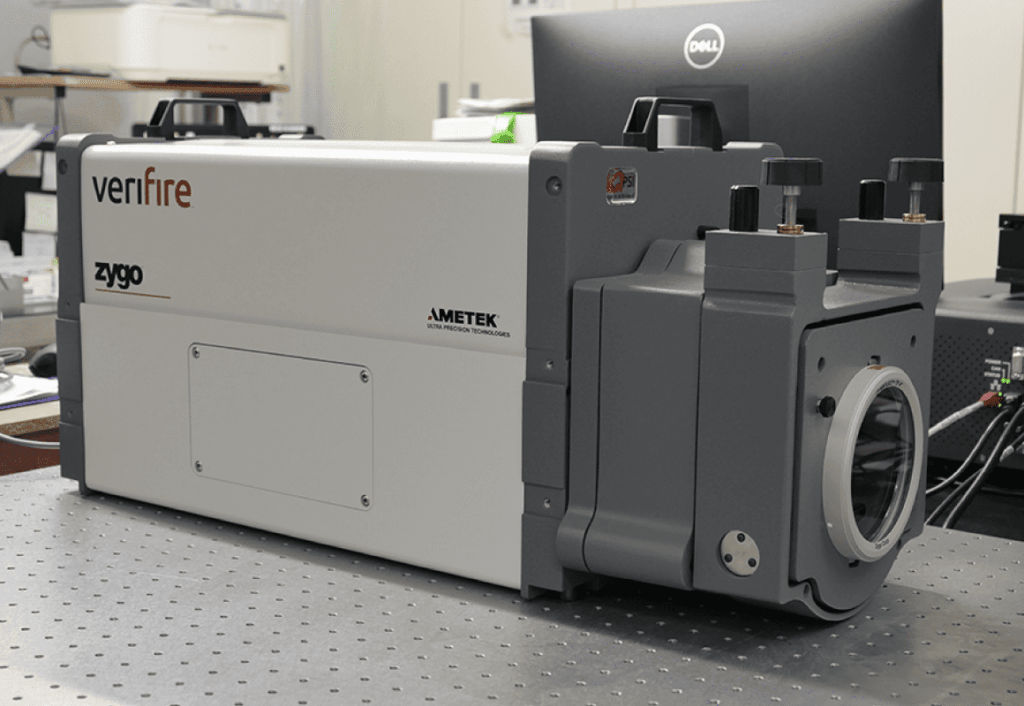

Laser Interferometer

Measurement accuracy of up to λ/20 can be achieved.

This system enables comparative evaluation of the substrate surface condition before film formation and the thin film surface after processing.

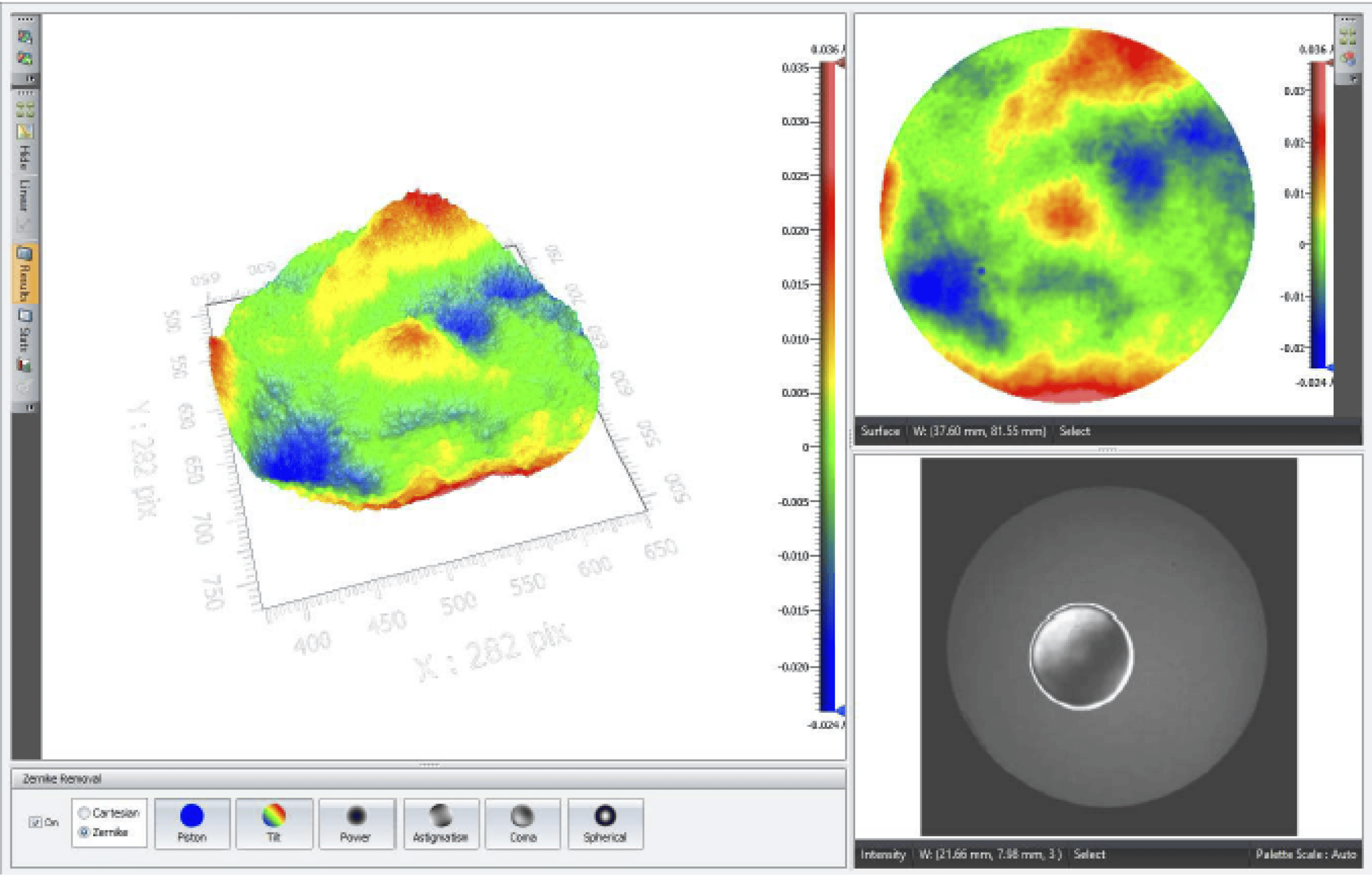

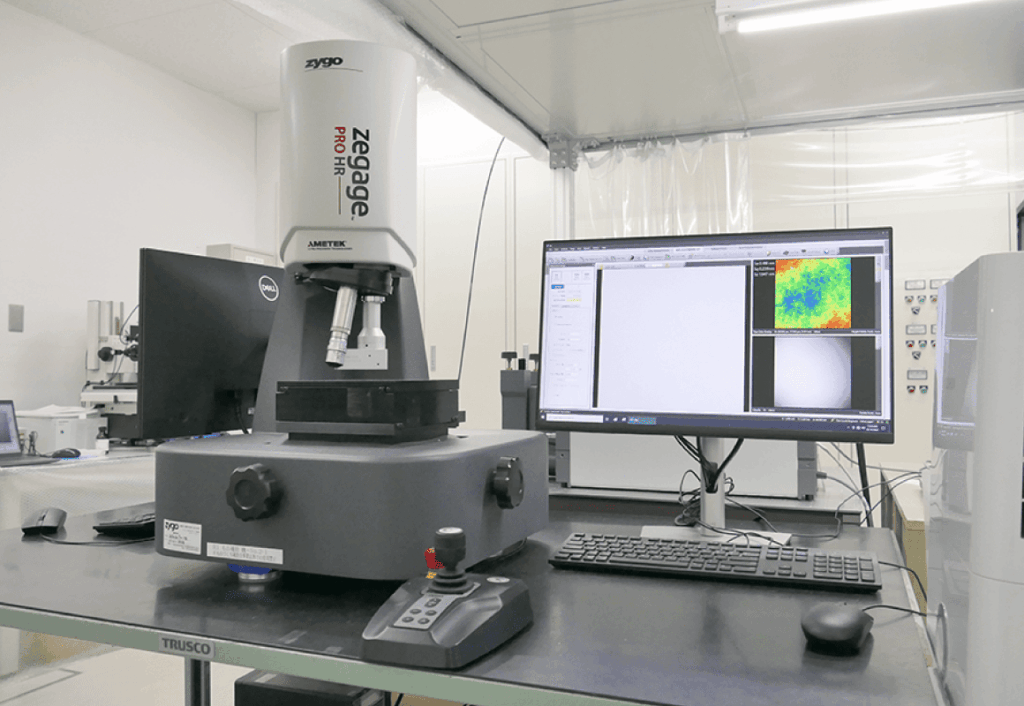

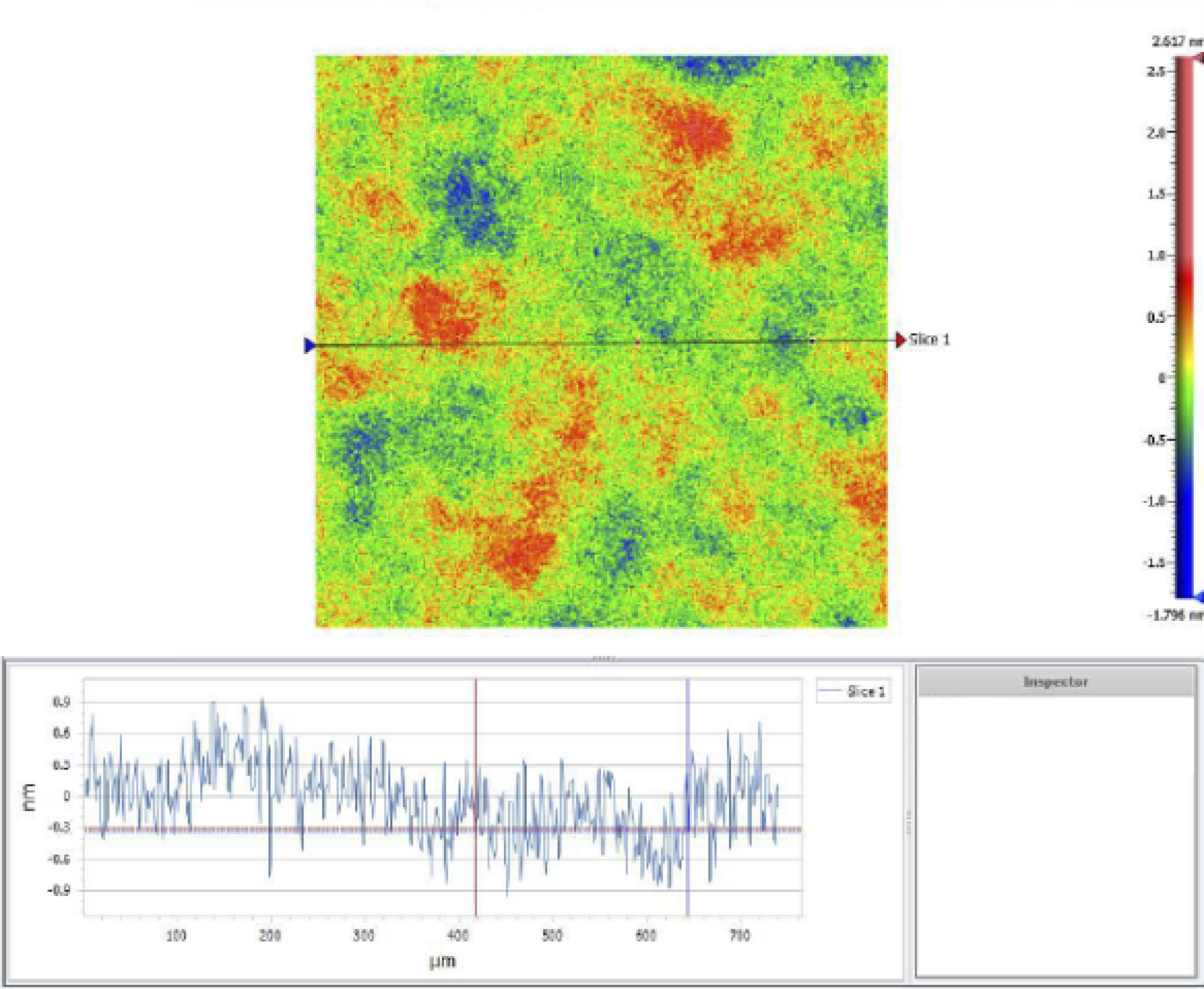

3D Surface Roughness and Profile Measurement System

This system enables non-contact three-dimensional evaluation and analysis of surface roughness and profiles of substrates at the nanometer scale.

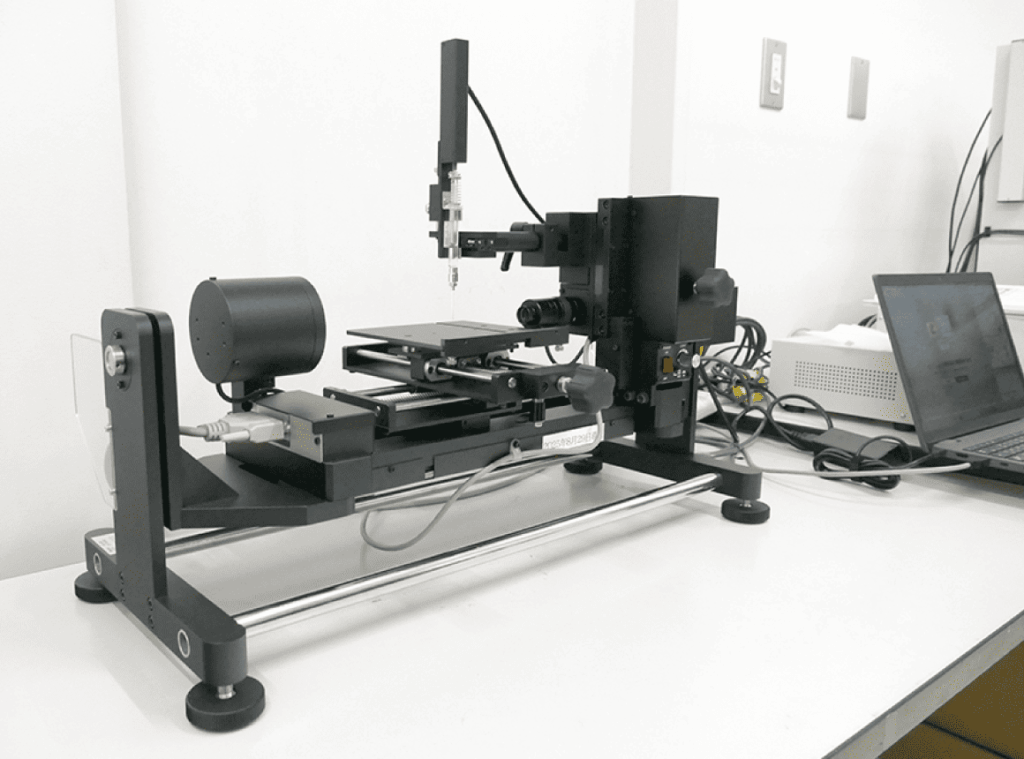

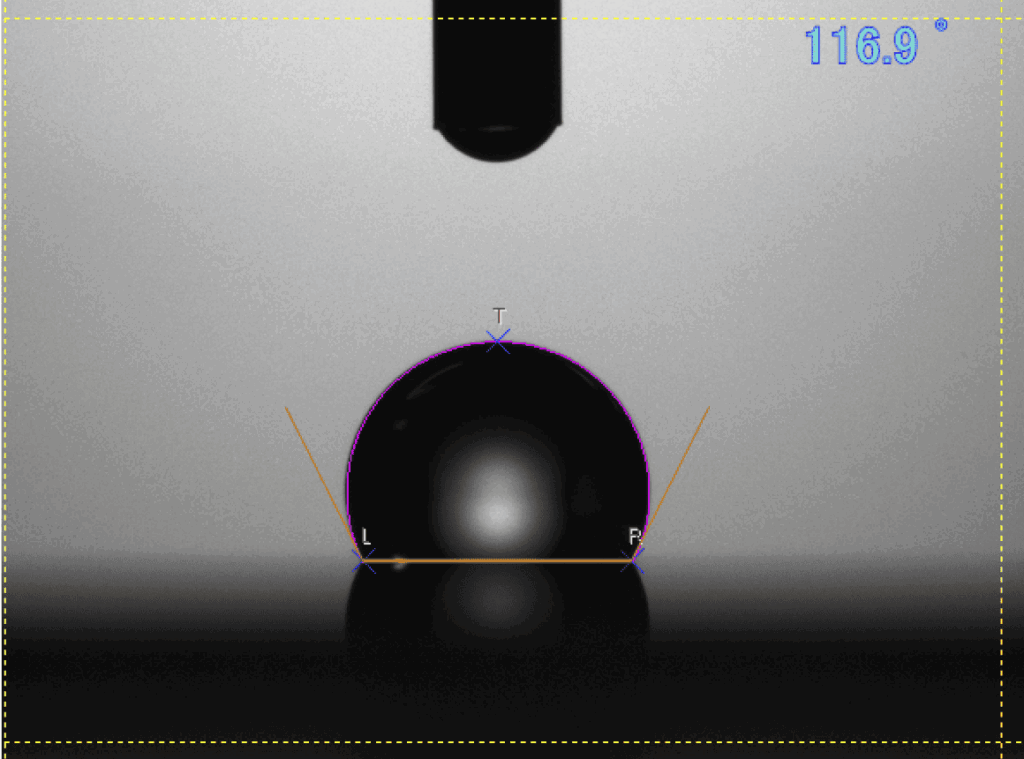

Fully Automatic Contact Angle Measurement System

This system enables measurement of contact and sliding angles when a liquid droplet is applied to a surface. It is ideally suited for evaluating water-repellent coatings based on contact and sliding angle measurements.

In addition to the equipment listed above, we maintain a wide range of measurement and evaluation instruments to enhance quality and reliability.

Measurement Instruments

- Spectrophotometers: 6 units

- Infrared Spectrophotometer

- Optical Microscopes: 2 units

- Image Dimension Measurement System

- Laser Interferometer

- Haze Meter

Evaluation Equipment

- Constant Temperature and Humidity Chamber

- Thermal Shock Test System

- High-Temperature Muffle Furnace

- Other Evaluation Equipment

Contact Form

Contact Form